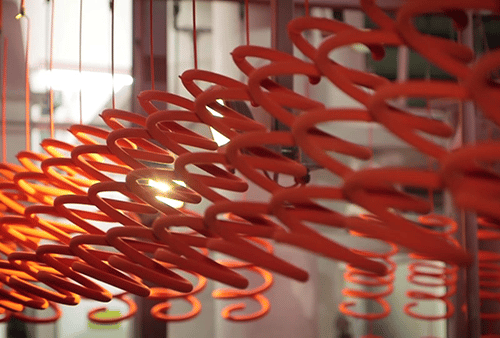

Specialist in oppervlakte behandelingstechnieken

indufinish

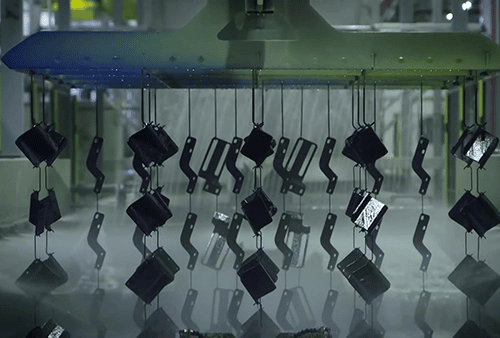

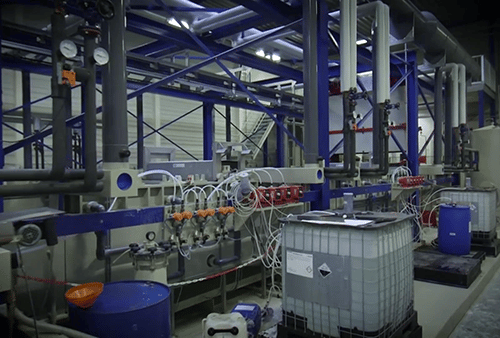

Indufinish is een leverancier van oppervlaktebehandelingsinstallaties. Al meer dan 25 jaar zijn wij een toonaangevende speler in onze branche. Zowel nationaal als internationaal. Daarbij richten wij ons vooral op poedercoaten, KTL en galvanotechniek.

Wij ontwerpen, leveren en installeren zowel componenten als complete coatinglijnen voor onze klanten. Ook kunt u bij onze deskundige medewerkers terecht voor advies over oppervlaktebehandelingstechnieken of het bestellen van spareparts voor uw coatinglijn. Na oplevering begeleiden we u met het trainen van uw medewerkers en het opstarten van uw productie. Daarnaast kunt u de service en het onderhoud van uw bestaande installatie door ons laten uitvoeren.

Indufinish b.v. | Willem Barentszstraat 5 | 7825 VZ Emmen | The Netherlands | +31 (0) 591 630 003 | info@indufinish.com